5S Guide and Checklists for Workplace Productivity

In the search for operational excellence, businesses are seeking methods to optimize their workplace productivity and improve organization and employee morale. The 5S Methodology, which came from Japan as part of Toyota's way of making cars, has ideas that can help with this.

Let's look at how to use a 5S Checklist to do checks and put the 5S process and methodology into action.

What is the 5S Methodology?

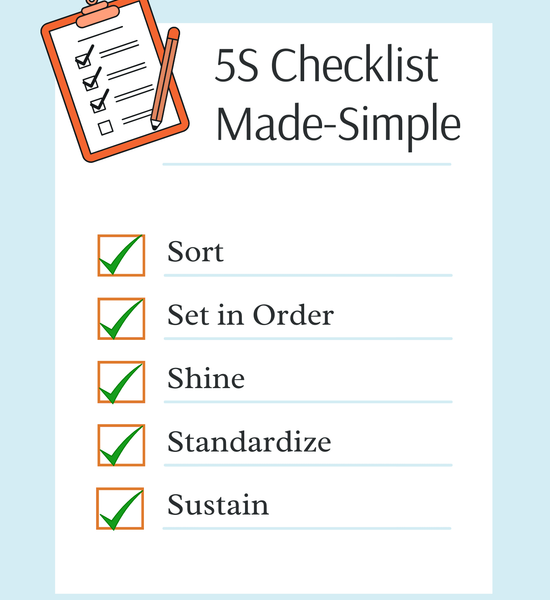

At the core of the 5S Methodology are five key principles known as the 5S steps: Sort Set in Order, Shine, Standardize, and Sustain.

These 5S standards aim to create a workplace culture that values getting things done well and always trying to do better.

Sort

- Goal: Get rid of stuff you don't need in your work area to cut down on things getting in the way and wasting time, which helps you work faster. People often use red tags to mark things that need to go.

Set in Order

- Goal: Make sure everything has its spot so you spend less time looking for tools or equipment, which helps you get more done. People often use things like shadow boards and visual aids to help with this.

Shine

- Goal: Keep things clean to create a healthy workplace and spot problems or broken equipment. People often use cleaning checklists for this step.

Standardize

- Goal: Make tasks and processes the same for everyone. This helps clear up who does what leading to smooth work with fewer mistakes. Standard work steps are crucial here.

Sustain

- Goal: Keep up and keep improving the steps you've put in place. This sets the stage for ongoing growth and reaching top-notch operations. Keeping 5S going is a never-ending job.

Benefits of 5S Checklist

Implementing 5S checklist offers many advantages to businesses. Here are some key benefits:

- Increased Efficiency: Organizing the workspace and eliminating unnecessary items helps employees find tools and materials quickly, reducing time wasted searching.

- Improved Safety: A tidy, well-organized workplace minimizes hazards, leading to fewer accidents and injuries.

- Higher Productivity: Streamlined processes and a clutter-free environment enable employees to work more effectively, boosting overall output.

- Higher Employee Satisfaction: A clean and organized workspace can boost morale, leading to higher job satisfaction and retention rates.

- Cost Savings: Reducing waste and improving efficiency can lead to significant cost savings in materials, time, and labor.

- Better Quality: Consistent organization and standardization help maintain high-quality standards in production and services.

- Better Space Utilization: Efficient use of space ensures that all areas are used optimally, potentially reducing the need for additional storage or expansion.

- Sustainability: Promoting better resource management and waste reduction supports sustainable business practices.

Checklists in the Digital Age

5S Audit Checklist in Lean Manufacturing

In the world of lean manufacturing, the 5S plays a key role in cutting waste, improving processes, and boosting output. Lean ideas like poka-yoke and Kanban systems often work together with 5S.

5S Audit Checklist Software

Mobile2b's platform offers a fully customizable digital 5S app solution tailored to your business needs. With extensive expertise in 5S methods and lean principles, we help companies implement effective 5S practices.

Start your journey today, try out our 5S Checklist App for free - integrate to your existing workflow and use on any device.

5S Checklist Examples from Top Companies

Real-world examples from businesses utilizing the 5S Methodology for efficiency, safety, employee satisfaction, and cost savings. Here are a few notable companies:

Top Industries and Companies Known for 5S Adoption:

Common Challenges in 5S Implementation

Companies often face several hurdles when they try to implement it. To make it work, it's key to understand the hurdles and plan how to get over them.

Resistance to Change

- Hurdle: Workers and bosses might not want to change how they do things. They might see 5S as extra work instead of a way to make things better.

- Plan: Create a workplace where people talk and get involved. Share stories of when 5S worked well and show numbers that prove how good 5S can be. This can get the team excited and ready to join in.

Insufficient Training

- Challenge: Misunderstanding the 5S principles can result in incorrect use reducing the method's effectiveness.

- Strategy: Offer thorough training sessions and materials. Make sure everyone involved understands each principle and how to apply it.

Sustainability Issues

- Challenge: Initial excitement for 5S often fades over time leading to less adherence to the established practices.

- Strategy: Set up regular check-ins and feedback meetings. Acknowledge and reward people for sticking to 5S practices to keep them engaged and motivated.

Lack of Continuous Improvement

- Challenge: Some companies treat it like a one-off project instead of something they should keep working on.

- Strategy: Make it a part of everyday work and long-term plans. Push for regular checks ask for feedback, and be ready to change things. This helps create a workplace where everyone's always trying to get better just like in Kaizen.

Conclusion

Starting with 5S might seem tough, but the key is to start small. Pick an area, get your team involved, and put the principles of Sort, Set in Order, Shine, Standardize, and Sustain into action. Seeing the good results yourself will push you to expand more and build a culture that keeps getting better. Keep in mind, that the road to running things better starts with using the 5S Method, bit by bit. Trailblazers like Taiichi Ohno and Shigeo Shingo set the stage for these game-changing practices - now it's our turn to take the lead and enjoy the perks of a neat productive workplace.

FAQ on the 5S Methodology

1. What is the 5S Methodology?

- The 5S Methodology is a structured approach created in Japan as part of the Toyota Production System to organize and manage the workplace. It stands for Sort, Set in Order, Shine, Standardize, and Sustain. This 5S method aims to boost efficiency, safety, and productivity in the workplace.

2. How can 5S improve workplace efficiency?

- By getting rid of unneeded items putting tools in order keeping things clean, making processes standard, and making sure things keep getting better, 5S cuts down on waste, makes operations smoother, and improves productivity. The 5S system is a key part of lean manufacturing and top-notch operations.

3. What is a 5S Checklist?

- A 5S Checklist helps people check and rate how well they're using 5S ideas. It shows where things can get better and makes sure everyone sticks to the plan in the same way.

4. How often should 5S audits be conducted?

- People should do 5S checks often if every day. This makes sure everyone keeps following the rules and keeps making the workplace more organized and better at getting things done.

5. Can 5S be applied in digital and virtual environments?

- You bet 5S principles work in digital settings too. People use things like digital checklists, systems to manage inventory, and software to handle projects. These tools make it easier to put 5S into action and check how it's going. This way, both real-world and online workspaces can get the perks of 5S practices.

6. What are the common challenges in implementing 5 S?

- The usual hurdles include people not wanting change, not getting what it's about keeping it going long-term focusing too much on cleaning, and treating 5S like a one-off task instead of an ongoing thing.

7. How can Mobile2b help with 5S implementation?

- Mobile2b offers digital 5S Checklist solutions you can customize. These tools make daily 5S audits easier, help businesses get better over time, and boost workplace efficiency. They know their stuff when it comes to 5S practices that fit your business needs. Their structured audits and tailored 5S methods pave the way for real change in how you work.

Related Posts

Couldn't find what you're looking for?